1. Introduction to Powder Coating Oven Gas Burners

Powder Coating Oven Gas Burners are critical components in powder coating ovens, providing efficient and consistent heat for curing powder-coated surfaces. These burners use natural gas or propane to generate high temperatures, ensuring even curing and durable finishes. Key components include the burner head, ignition system, fuel supply line, and temperature control unit.

2. Applications of Powder Coating Oven Gas Burners

These burners are widely used in industries like automotive, aerospace, and metal fabrication. They are essential for curing powder coatings on car parts, machinery, and industrial equipment. Their ability to deliver precise, high-temperature heat makes them ideal for high-volume production lines.

3. Price Range of Powder Coating Oven Gas Burners

Prices range from 500forbasicmodelsto5,000+ for advanced units with automated controls. Factors influencing cost include heating capacity, fuel efficiency, and additional features like temperature monitoring. While initial costs may be high, their efficiency reduces long-term operational expenses.

4. How to Use a Powder Coating Oven Gas Burner Correctly

Ensure proper installation and connection to the fuel supply.

Set the desired temperature using the control unit.

Monitor the curing process to avoid overheating or under-curing.

Regularly inspect the burner and fuel lines for leaks or damage.

Follow manufacturer guidelines for safe and efficient operation.

5. Tips for Choosing a Powder Coating Oven Gas Burner

Heating Capacity: Select a burner that meets your oven’s size and temperature requirements.

Fuel Efficiency: Opt for models with high thermal efficiency to reduce fuel costs.

Automation: Choose burners with automated controls for precise temperature management.

Durability: Look for robust construction to withstand high temperatures and frequent use.

Brand Support: Prioritize suppliers offering warranties and technical assistance.

6. Safety Precautions for Powder Coating Oven Gas Burners

Ensure proper ventilation to prevent gas buildup.

Regularly inspect fuel lines and connections for leaks.

Install carbon monoxide detectors near the oven area.

Train operators on emergency shutdown procedures.

Avoid operating the burner in poorly ventilated or confined spaces.

7. Design Advantages of Powder Coating Oven Gas Burners

These burners are designed for efficiency and reliability. Features like precise temperature control, high thermal efficiency, and durable construction ensure consistent performance. Their compact design allows easy integration into existing ovens, making them a cost-effective heating solution.

8. FAQs on Powder Coating Oven Gas Burners

Q1: What industries use powder coating oven gas burners most?

A1: Automotive, aerospace, and metal fabrication industries rely on them for curing powder coatings.

Q2: How to troubleshoot uneven heating?

A2: Check burner alignment, clean the burner head, and ensure proper fuel flow.

Q3: Can these burners use alternative fuels?

A3: Most are designed for natural gas or propane; check compatibility before use.

Q4: What maintenance ensures long burner lifespan?

A4: Clean the burner head regularly, inspect fuel lines, and replace worn components.

Q5: Are gas burners eco-friendly?

A5: Modern burners are designed for high efficiency, reducing fuel consumption and emissions.

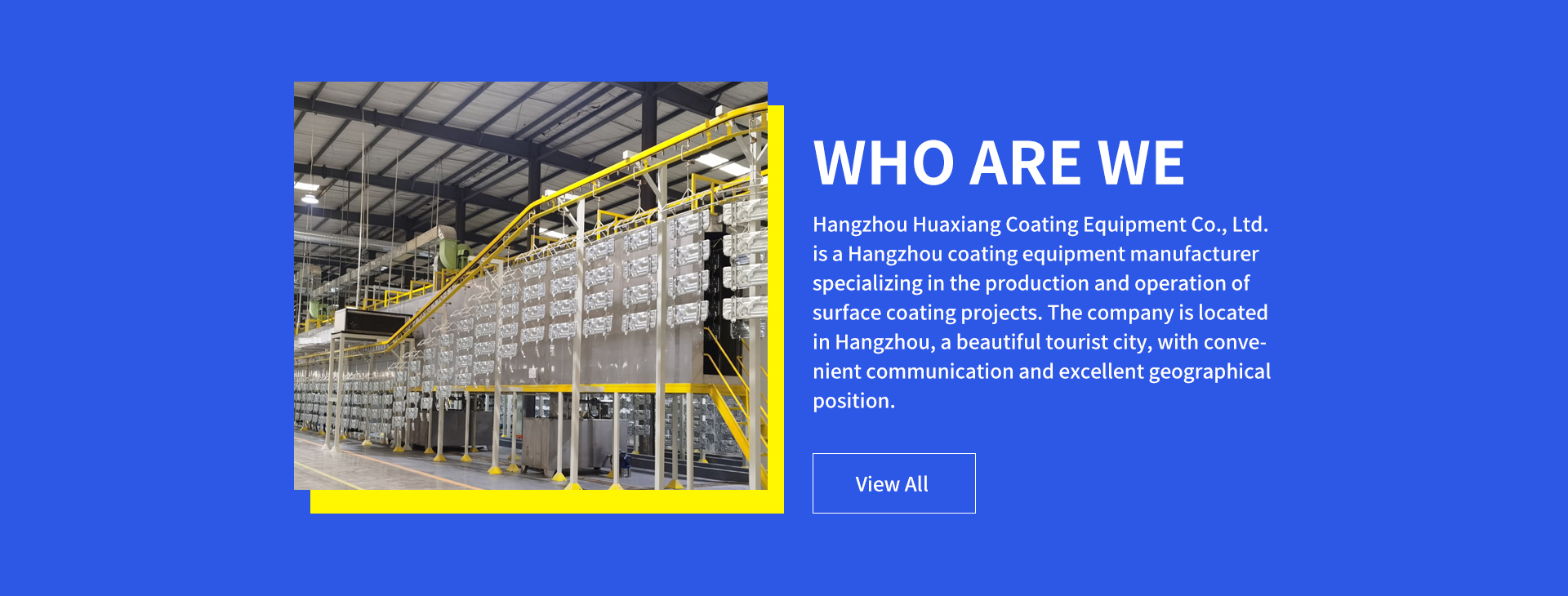

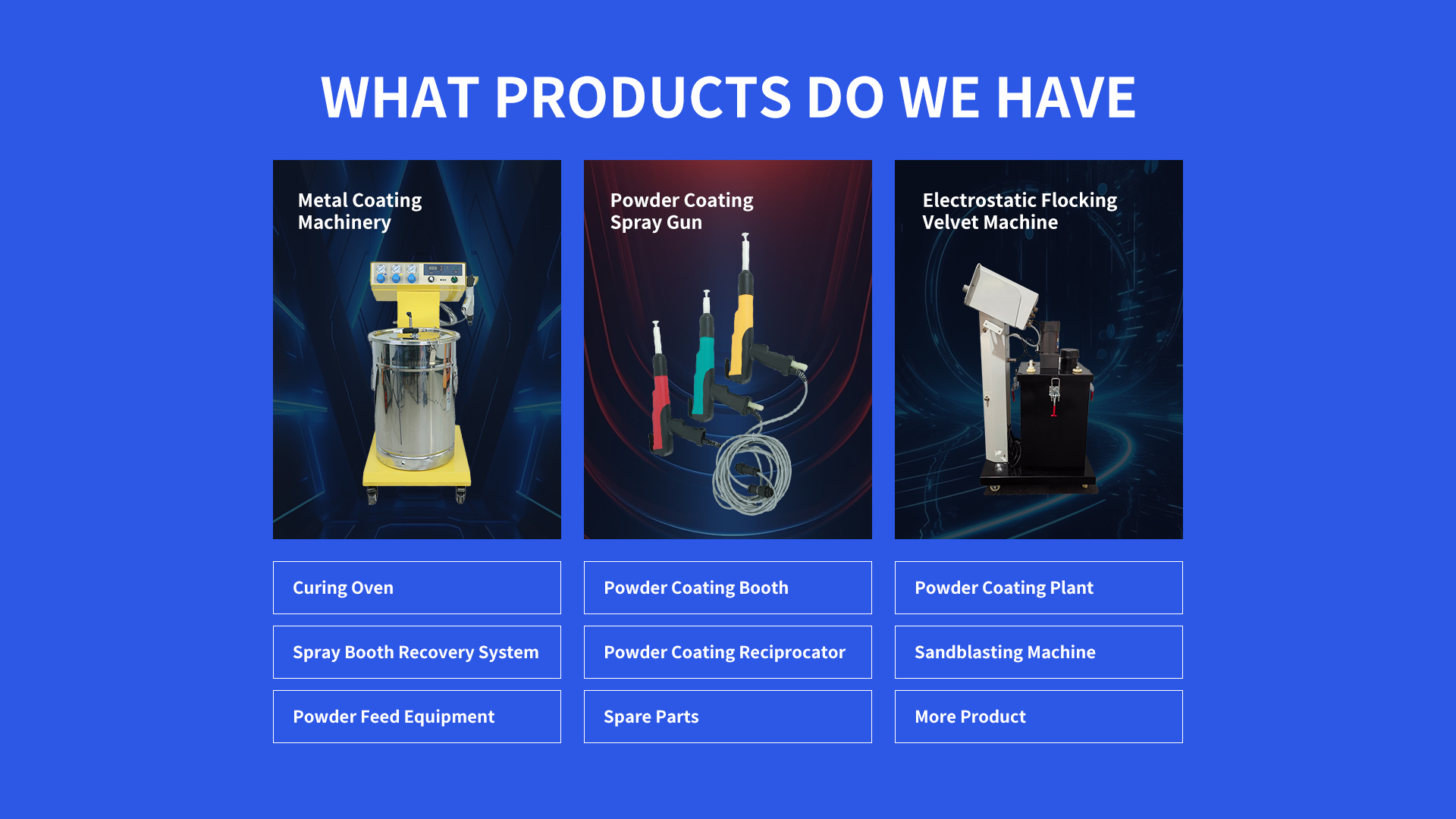

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com