Guiding and Tracking Devices: These devices keep the conveyor belt on track and prevent slipping. They include side guides, tracking rollers, and tensioning mechanisms. Side guides keep workpieces in place, while tracking rollers and tensioning mechanisms maintain the belt's tension and alignment.

Automotive Manufacturing: Move car bodies, engine parts, and wheels for even powder coating.

Aerospace Industry: Transport aircraft components like landing gear, engine casings, and wing sections for consistent coating.

Home Appliance Production: Move metal parts of appliances for a protective and nice - looking finish.

Prices vary based on factors:

Basic Systems: For small - scale or low - volume production, with simple components, cost $3,000 - $8,000.

Mid - Range Systems: With better belts, precise speed control, and enhanced guides, cost $8,000 - $20,000 for medium - sized facilities.

High - End Industrial Systems: For large - scale, high - volume production, with large - capacity belts and advanced features, cost over $20,000.

Pre - operation Checks: Inspect the belt for wear, check drive mechanism lubrication, and secure electrical connections. Set the speed.

Operation: Load workpieces properly, start the conveyor, and keep the speed constant during coating.

Post - operation Maintenance: Clean the belt and guides, check for abnormal noises, lubricate moving parts, and replace worn components.

Production Volume: Choose a large - capacity, high - speed system for high - volume production; a compact, basic one for small - scale.

Workpiece Characteristics: Consider size, weight, and shape. Pick a belt that fits and has enough load - bearing capacity. Look for special fixtures for irregular workpieces.

Budget: Set a realistic budget but don't sacrifice quality. A better system may save money long - term.

After - sales Service: Select a supplier with reliable support, spare parts, and maintenance.

Guarding: Install fences, covers, and interlock systems to prevent contact with moving parts.

Emergency Stop Buttons: Place easily accessible buttons along the conveyor and test regularly.

Electrical Safety: Ground electrical components, inspect wiring, and use protective devices.

Load Limit Adherence: Don't overload to avoid belt and drive mechanism damage.

Efficiency: Enables high - volume, continuous coating, reducing manual handling and human error.

Consistency: Precise speed control ensures uniform coating thickness and quality.

Customization: Can be customized for different workpiece shapes, sizes, and production volumes.

Q: What if the conveyor belt sags?

Q: Can it be used in a high - humidity environment?

Q: How often replace the conveyor belt?

Q: What if the system stops unexpectedly?

Q: Can I install additional sensors?

Title:Unleash the Potential of Powder Coating Conveyor Systems: Your All - Encompassing Handbook

Link:http://www.hpowdercoating.com/industrynews/show/700.html

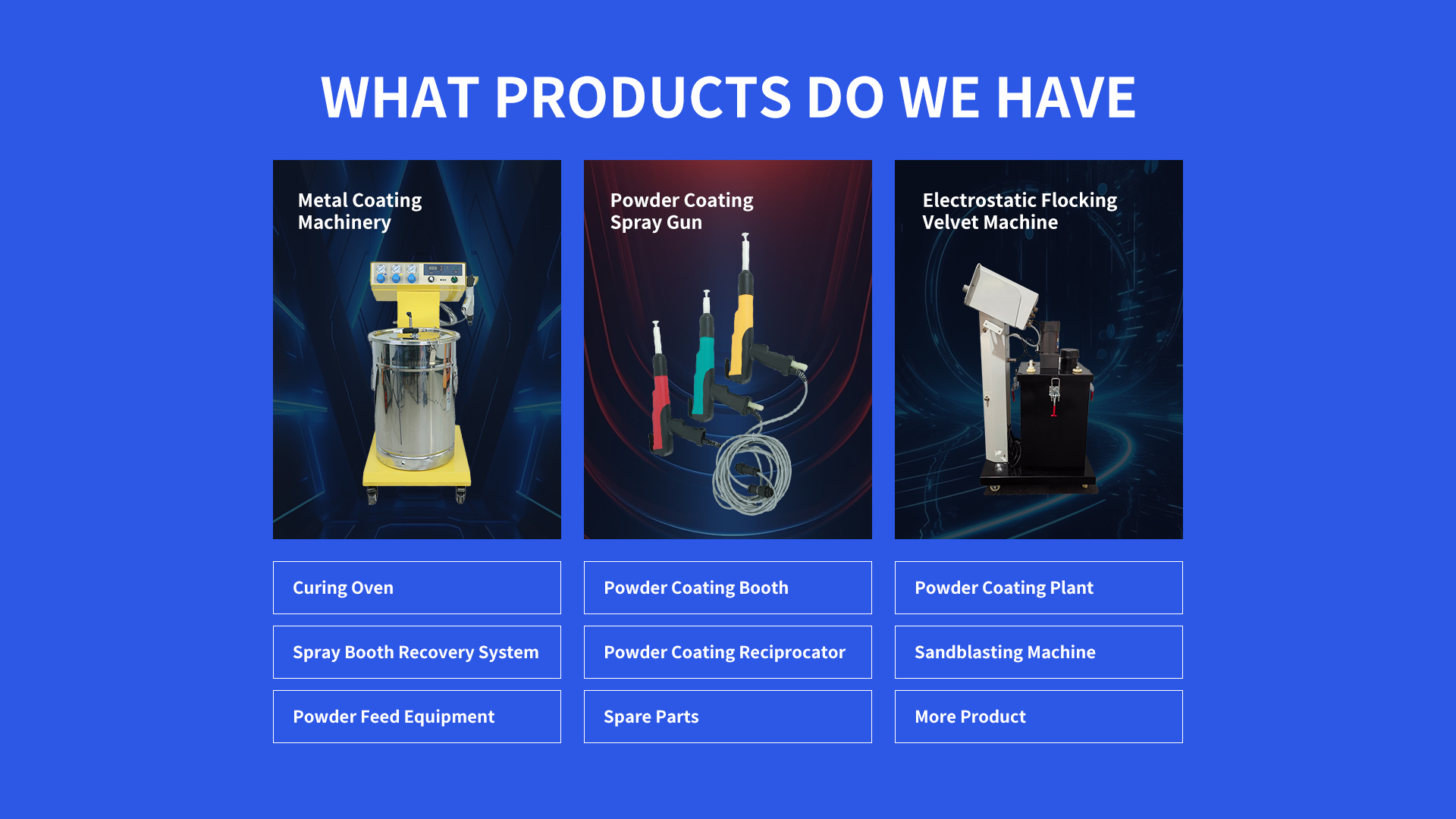

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com